Bike pumps are an essential tool to have for any cyclist, and it helps to have one on hand at all times. But how does a bicycle pump work?

Pumps work by controlling the pressure inside them. Air is gathered in the cylinder and is compressed through the hose and into the tire. Let’s learn more about these gadgets, including bicycle pump works on which law of physics.

Keep reading to learn more.

Table of Contents

How It Works and Main Parts of a Bike Pump

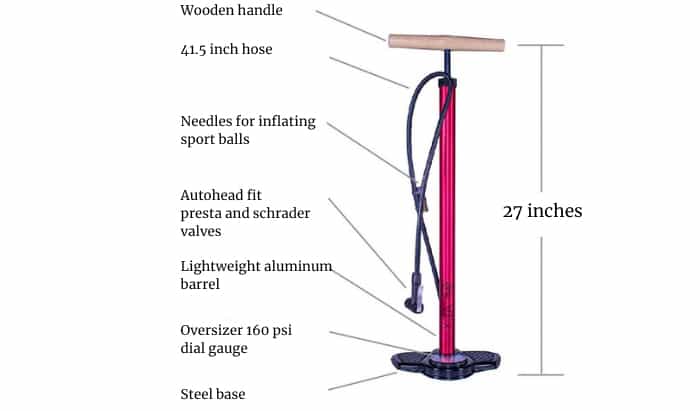

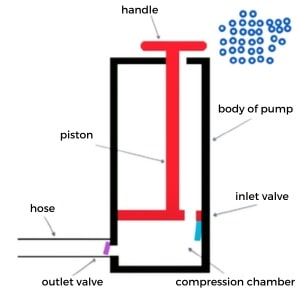

The primary mechanism of a bicycle pump requires it to have a few main parts, namely the cylinder, handle, hose, and piston. The hose is connected to the tire valve, and it is only through this channel that air may flow into the tire.

The valves are hollow tubes with different sizes depending on the type, but most are connected to a tire’s inner tubing.

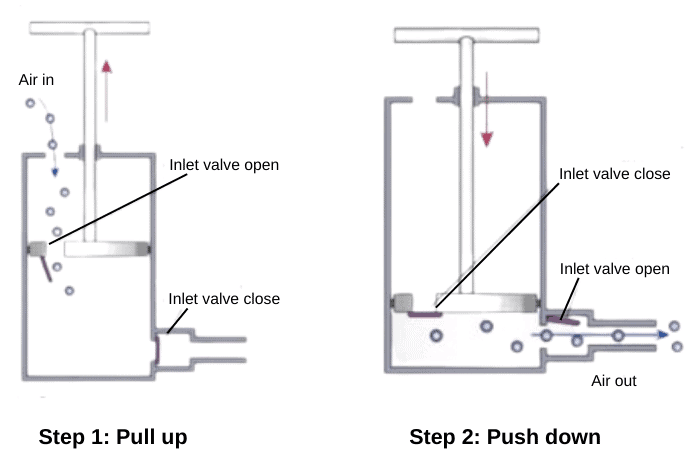

To further understand how a bike pump work, we can look at Boyle’s law, which states that the pressure of a gas is inversely proportional to its volume. The cylinder is hollow and when the piston is raised, the pressure drops and air gathers, creating a vacuum.

When the piston is forced down, it increases pressure by compressing and lowering the volume of gas. An attached plunger forces the accumulated air through the hose and into the inner tube of the tire. By repeating this process, we can fill the tire with air until it is firm enough for use.

It is also a good way to illustrate how the 1st law of thermodynamics works. Bicycle pump thermodynamics manifests in how the pump heats up as it is used continuously. Refer to a bicycle pump diagram to better visualize the process.

What is It?

A bicycle pump is a tool used to inflate tires by filling them with air. We also use them to gauge and apply the necessary pressure to make bike tires work well. It is helpful to have one of these during your ride in case of tire emergencies, but carrying them can be a problem.

There are different types of pumps, and they operate in a similar way to what is described above, but there are some differences in how they are used. Each type has its advantages and disadvantages.

Types of Bicycle Pumps and How They Are Used

1. Stand or floor pump

This is probably the most common type and is placed on the floor and then secured with your feet while in use.

It is operated by pulling on the handle to draw air into the cylinder and then pressing down on the handle to close the inlet valve and keep the air inside the compartment. With no other way to go, the air goes through the hose and into the tire.

- Works with different valve types

- Efficient and requires less time to use

- Takes up a lot of space

- Costs more

2. Hand pump

Also called micro or mini pumps, these are small and portable designs that are made to be easy to carry. They work in a very similar way to stand pumps but may or may not have a tube to connect to the tire valve. When you pump a bike tire with a hand pump, it takes more time compared to other types.

- Easy to carry

- Low cost and may even be free

- Takes effort and time to use

- No pressure indicator

- May leak air if you use the tube type instead of the integral type with a rubber seal

3. Foot pump

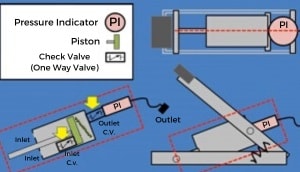

This type is placed on the ground and operated by foot. These are mainly used for cars and are limited to specific valves, but you can use foot pumps for bicycle as well. It is limited in the amount of pressure it can apply, usually maxing out at 100 psi.

When you press the pump down, the inlet check valve lets air fill the piston chamber. Later, when the pedal moves back up to its original position, the air is sent through the outlet check valve into the tire.

Because the pump lever springs back up, it does not take much strength to use, but it does require significantly more repetitions to fill a tire with air.

- Easy to use

- Only usable with Schrader valve

- Limited tire pressure

4. Electric pump

This type of pump performs the same function as other types but has an electric motor to gather air and push it through to the tire tube. Because it possesses a motor, it is the easiest type to use, especially compared to when you use a handheld bike pump. You only need to input the right pressure and leave it to work.

However, the demand for charging keeps its applications limited when you air pump bicycles using this type.

- Automated operation requires the least effort.

- Accurate and high-pressure settings

- Very costly

- Requires power or charging

- Loud during operation

- A broken seal can be replaced by detaching the pump’s head.

- Sounds of hissing from the hose may mean there is an air leak. In this case, check for tears in the hose and replace it if necessary.

- Ensure that you are using the pump with the correct valve. If the two are compatible and the pump won’t fit the valve, replace the pump head.

- The seal and plunger need to be lubricated from time to time, particularly when it’s hard to press the pump or the tool makes noise during use.

- Check the rubber on the pump nozzle. If it’s worn out, the pump might have trouble attaching itself to the tire valve. In this case, replace the nozzle.

Different Type of Bike Pumps Valves

1. Presta

These are used exclusively with bicycle tires with smaller valves that are just 6mm wide. The valve is secured by a nut that locks its pin in place.

This lock nut needs to be loosened before the pin can be pressed and any air is released. Hence, Presta valves are more secure when it comes to keeping the air in compared to Schrader valves.

2. Schrader

These have been around since the 1800s and are the common types found on many bikes and are also seen on car tires. It has an 8mm wide valve that adheres to the standard design that most bicycle tires have.

A pin can be found at the core of the valve, and this is connected to a spring that seals air in; pressing on this pin releases air. It also comes with a dust cap that closes off the valve in case the pin fails to seal the air inside. Schrader valves are also more durable but compromise the wheel rim’s strength.

3. Dunlop or Woods

This type is similar to a Schrader valve but works with a Presta-compatible pump as well. It has a cap to seal it but also uses a core nut that needs to be pulled out and removed when deflating the tire.

This type of valve is difficult to find in the US but is still common in developing countries and parts of Europe. Its biggest advantage is its ease of use due to not needing any specialized tools to work with or install.

Conclusion

How does a bicycle pump work? Now, you have a better understanding of this topic, including some basic points regarding bicycle pump physics. It helps to know how these tools function, especially if you’re choosing one to use on the road.

What is your preferred type of pump and valve to use for your bicycle? What do you think is the most important thing to consider when choosing? Tell us your thoughts about this in the comments section below.

Always ride safely.

Related:

“I ride my bike to work for years, but is that enough? Our carelessness towards our surroundings has taken a toll on the environment. And now, everyone is responsible for changes; even the most minor contribution is counted. With this hope and spirit, I started with my partner to establish Biketoworkday to help more individuals commute to their work sites on their bikes.”